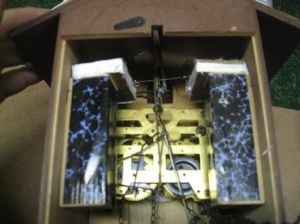

The bellows on this old cuckoo clock have deteriorated. I acquired some bellows material and spent a few hours doing the repair. The clock was made by the Cuckoo Clock Mfg. Co. Inc. The movement is stamped “Made in Germany” with a model number “100/171”. The cuckoo is wooden (not plastic) which dates the clock as pre-1945, one of the first clocks distributed by the company.

The bellows material crumbled when touched.

This clock was made by the Cuckoo Clock Mfg. Co. Inc., thought to be owned by Irving and Max Schulman, brothers and Jewish refugees who fled Germany during the 1940s. They set up a shop in the Gift District of NYC and rather than manufacture clocks, they decided to import clocks instead.

There were three families, living in the Black Forest region of Germany, who were believed to have exported clocks for the Schulman brothers. The family names were Herrs, Kammerers and the Bergers. Later in the 1950s, certain clocks bearing the name “Linden” contained movements stamped with the name “Cuckoo Clock Mfg. Co.”

Schulman divested his interest in the company over time. One of the buyers may have been Max Adler who became the owner and retired in 1988.

Record the travel distance of the bellows.

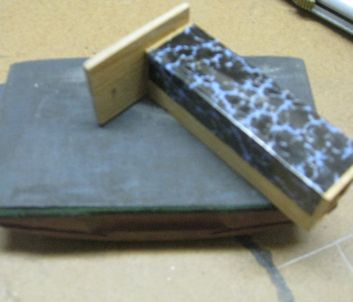

In this photo I recorded the maximum opening distance on my work board.

“In the late 1950’s when the Cuckoo Clock Manufacturing Co. started making non-cuckoo clocks the name didn’t fit so Linden was added – Linden Cuckoo Clock Manufacturing Co. Later the company was sold to the Colibri group and just the name Linden was used. Up until the mid/late 1980’s the non-cuckoo clocks were made in the 25th street New York building but then moved to Rhode Island. Now they’re made mostly in Taiwan.” [source]

Select the right tool to use to trim the old material from the blocks.

With the gap measured, it is time to remove the old bellows material. For this operation I will be using a pipe wrench, an awl, a ball peen hammer and a dry wall knife. It is always best to select the right tool for the job!

“My father, Fred Gold, in the 1960’s and 1970’s, was one of the owners of Cuckoo Clock Mfg, along w/ Max Adler. One other minority partner was Walter Fleischer. I worked for the clock company from 1979 through 2009.

Where did the name “Linden” come from? The company wanted a brand name for their clocks. Cuckoo Clocks were made from the wood of the Linden tree. Thus the name Linden.

Cuckoo Clock Mfg (on some of the mechanical movements you often saw the initials CCM standing for Cuckoo Clock Mfg.) started with cuckoo clocks but branched into a full line of clocks (with the exception of grandfather clocks). The company also carried a line of music boxes that were sold to gift and jewelry stores across the USA. Cuckoo Clock Mfg. / Linden was always known as an innovative company and a company with great integrity. It was a real American success story.

The company changed ownership several times in the mid to late 1980’s. It was sold to Colibri in 1991. Colibri later bought the brand name SETH THOMAS and much of the clock offerings were sold under the SETH THOMAS name as opposed to the Linden name. Colibri went out of business in January of 2009. Colibri is back in business – owned now by a company called Alliance Time (based in New York). Most of the clocks they sell now are under the Seth Thomas name. I do believe they own the Linden brand name.” [ibid]

Gently sand the old material from the block edges.

The material has been removed. A small block sander is used to dress the wood to prepare it for glue. I will use a special white glue to make the repair.

After making a hinge for the back, I cut a swath of the bellows material and glued the opposite edges to material. I applied glue to the right edges and wrapped the material upward, pressing it into place.

Bellows material is wrapped and glued to the blocks after a hinge is glued into place.

Glue is then applied to the top edges and the cloth material is wrapped and pressed into place. After the glue dries, I trimmed the excess material with a small razor knife.

The bend in the cloth is not too difficult. As the bellows shut, a straight edge is used to help create a crease in the front. The material wants to expand outward on the sides, so as the bellows shut, the straight edge is used to maneuver the side bend inward. With only a gentle touch, the shape of the bellows appears in the cloth.

Use a straight edge to create the desired creases.

The bellows assemblies are now ready to be returned to the clock.

The bellows are ready to be returned to the case.

The bellows are returned to the case.

With the bellows repaired and functioning, I can now proceed with the cleaning and adjustment of the clock movement.

You must be logged in to post a comment.